Jeep Suspension | Jeep Control Arm

Jeep Adjustable Control Arms Smooth Off-Road Ride

Jeeps were born during World War II when the US Army discovered the need for a lightweight, versatile reconnaissance vehicle. The original designer of the Jeep was The American Bantam Car Company out of Butler, PA. However, Willys and Ford took over making Jeeps for the military during the war. After the war, production remained with Willys, which is now under the Chrysler Group LLC umbrella of vehicles.

Why are Jeeps so Popular?

Over the years, Jeeps became extremely popular due to their off-roading capabilities. They are light, small, and can be modified to maneuver over extreme terrain.

Based on the original Bantam design, the most popular model in the Jeep lineup is the Wrangler. The company has sold almost two million Wranglers in the past ten years. Even so, the comfort and features of the modern Jeep bear little resemblance to the ride offered to soldiers in WW II and have added to its popularity.

What makes Jeep Different?

What makes Jeeps truly trail-worthy is the suspension modifications available for them. One of the components G Force Performance Products set out to improve is the rear control arms which are a vital part of the overall suspension system.Benefits of lifting a Jeep

Most people that complete a Jeep Lift are looking for one thing—ground clearance. It's important because many of these vehicles are for off-roading. When navigating rough terrain, the extra ground clearance helps the vehicle overcome obstacles.

In addition to the ground clearance, you can go with a bigger tire which is also a tremendous benefit when off-roading and clearing obstacles.

Jeep Suspension and Control Arms

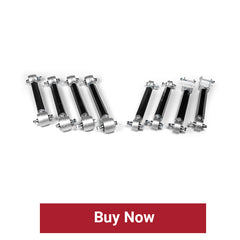

Control arms attach the tires and axle to the Jeep frame and ensure proper steering, vehicle handling, and tire rotation. As the terrain changes, the control arms support the vertical motion of the tires as well as keep the axle centered front to back. Factory-installed control arms often do not hold up to extreme off-roading and don't give you the articulation needed to travel over rough terrain.G Force control arms are made from 7075 T6 Aluminum with Forged steel Johnny Joint rod ends, making them stronger and more durable than their factory counterparts.

G Force offers a full kit comprised of front and rear, upper and lower control arms. These double adjustable linkages make adjusting the pinion angle of both the rear and front end a breeze. The upper arms are primarily used for pinion angle adjustment, while the bottoms help center the axle in the wheel well. Together, the control arms work to stabilize the axles under the frame and transfer power to the ground.

Johnny Joints Make Adjustments and Articulation Easier

Johnny Joints or spherical rod ends, are crucial when considering the articulation of the axles when jeeps are taken off-road. When one wheel raises, it shifts the whole axle vertically, plus the control arms also want to twist or articulate to accommodate the change of angle.The majority of the cheap control arms on the market use solid rubber or poly bushings in their ends. Poly bushings tend to bind up when the axles try to move. Our Johnny Joints allow flexibility and movement in a range of angles so the suspension can move freely but also helps dampen vibrations because of the poly bushing inside.

Another thing to consider is adjustability. Some cheap control arm brands are either a fixed length or "single adjustable." Single adjustable control arms require the user to unbolt the arm, unthread the rod end and guess where it needs to be, reinstall it, and hope it is in the correct place.

Our control arms are double adjustable, which means the center section is tapped with left-hand threads on one side and right-hand threads on the other, and the Johnny Joint rod ends to match.

This configuration allows the user to install the control arms, loosen the jam nuts, and turn the hex aluminum center to make the arms longer or shorter while the control arms are in place. The user can fine-tune their alignment and pinion angle without having to uninstall and reinstall the control arms.

As outlined above, G Force machines our control arms from aerospace grade 7075-T6 1-1/2" hex aluminum centers and heavy duty 4130 heat treated Chromoly steel rod ends. The hex aluminum looks cool and provides a place to put a wrench on when adjusting these on the vehicle. The cheaper control arm versions are fabricated from steel tubing and use bushings in the ends.

Aerospace grade aluminum provides strength while saving over 20lbs per set over steel. The anodized aluminum looks great while never rusting as steel would.

The G Force Adjustable Jeep Control Arm Kit

Our control arm kit is specific to lifted 1997-2006 Jeep Wrangler TJ/LJ. These models utilize the previously described Johnny Joint rod ends. Machined from Aerospace Grade 7075 T6 Aluminum, the body of the control arms has durability and strength. The control arms are 100% adjustable while remaining on the vehicle. Upgraded mounting hardware is included.

Another Popular Jeep Product from G Force

G Force also offers a Jeep Wrangler TJ Fuel Pressure Regulator Delete. Part Number GF-JFRD-V2 to bypass the OEM fuel pressure regulator and replace it with a billet aluminum version.

You can discover more information about our line of Suspension Components in these popular articles:

- Suspension System Vital to Handling and Ride

- What is a Rear Control Arm?

- G Force Performance Products Introduced a New Line of Suspension System Components